Saturday, July 22, 2006

NPR: managed health care

As health care reform sweeps the nation, medical facilities are accepting the idea that managed care will be in their future. But the competition that comes with change is hard for others to accept. From Wenatchee, Diane De Rooy has the story.

DIANE

A year ago, the Wenatchee Valley Clinic saw the handwriting on the wall, and the message was: managed health care is coming. Since day surgery is a large part of managed health care, the clinic began negotiating with Central Washington Hospital for use of its facilities.

But according to Dr. Chris Stahler, clinic board chairman, hospitals have very high built-in costs, prohibitive to the basics of managed care. Central Washington Hospital preferred not to negotiate on prices, he says.

The clinic felt compelled to construct its own facility, adjacent to its own doctors’ offices, to keep surgical costs down. The hospital saw that it could lose a great deal of market share, since clinic doctors perform more than half of the day surgeries now using hospital facilities.

Stahler sees more opportunity for cooperation between the two entities. The Rockwood Clinic in Spokane uses a surgery facility built for and leased to them by Sacred Heart Hospital, he says.

But negotiations between the hospital and clinic broke down repeatedly. Bulldozers are now busily taking up the asphalt where they are breaking ground for the clinic’s new day surgery facility.

Wednesday, July 19, 2006

NPR: Growth Management Act protest

What works in New Mexico won’t work in Washington. That argument is at the core of citizen protest in Chelan County against the so—called “Catron County” ordinance county commissioners want to adopt. Diane De Rooy reports.

DIANE

Some 500 counties throughout the West, including Chelan County, are considering a county ordinance based on the law in Catron County, New Mexico.

Similar legislation has already been overturned on legal challenges in Walla Walla and in Boundary County, Idaho. And even though Washington attorney general Christine Gregoire and Chelan County Prosecutor Gary Riesen have already issued statements advising against adopting the ordinance, Chelan County commissioners are moving swiftly ahead to approve it.

The Catron County ordinance model attempts to take powers away from state and federal agencies. Opponents point out that the areas affected include the Federal Clean Water Act, the Shorelines Management Act, and the state’s own Growth Management Act. In courts in Bonner’s Ferry, Idaho, and Walla Walla, Washington, these efforts to circumvent state constitutions have been found illegal.

Chelan County commissioners have already missed several deadlines for complying with the state’s Growth Management Act. Opponents see this proposed legislation as an attempt to further avoid filing a comprehensive plan.

Commissioners have called a public hearing to be held Tuesday, September 27th for citizen input regarding this proposed law. Opponents plan to marshal their resources for a public protest at that time.

For Northwest Public Radio, I’m Diane De Rooy.

NPR: Growth Management Act, public power

A Catron County-style ordinance in Chelan County could have negative effects on the ecology of the five valleys within. Yet there is serious support for such an ordinance. Diane De Rooy explains why.

DIANE

Most supporters of the proposed Chelan County “Wise Use” ordinance are senior citizens. They are farmers, hunters, landowners and pioneers.

Curt Epperson, an attorney from Manson, claims the feds have declared war on Chelan County. Epperson has assembled an extensive clipping file of outrageous government boondoggles. He uses these examples to show that the government is corrupt and must be replaced by right thinkers.

Perhaps most inflammatory to old farmers and grangers in Chelan County has been the recent argument between hydroelectric projects and free salmon runs. Interior Secretary Bruce Babbitt has stated that there are too many dams, and that he’d like to tear one of the big ones out.

Them’s fighting words in Chelan County, where the Grange Movement of the 1930s brought public power to the state and progress to farming.

Even though the Wise Use ordinance cannot succeed as written, it is the only weapon supporters feel they have right now to fight a government they believe is out of control.

For Northwest Public Radio, I’m Diane De Rooy.

NPR: Growth Management Act, housing

One phase of the state’s comprehensive Growth Management Act requires that local governments provide for adequate low—cost housing. Wenatchee is the first city in Washington State to propose meeting those requirements by allowing manufactured housing throughout the city. Diane De Rooy reports.

DIANE

A population boom in the Wenatchee Valley has sent housing costs up, while wages have remained relatively low. As a result, affordable housing has been priced out of reach for about half of the population.

The city’s planning department has proposed an ordinance allowing manufactured housing to be sited without discrimination throughout the residential area.

But some local citizens are opposed to the ordinance, envisioning barren city lots occupied by aluminum—clad mobile homes. City planner Bob Hughes says that stigma is well deserved. But he adds that the industry has responded to complaints of shoddy construction by making their homes solid and aesthetically pleasing.

Since the Uniform Building Code requires that a manufactured home must cost more than the price of the lot, Hughes thinks most homes will cost about $80,000, an unheard—of price for a home in Wenatchee today.

He adds that the distinction between “affordable” and “low-income” housing needs to be considered by neighbors and the real estate industry.

Hughes says allowing more manufactured housing will lessen the margin between homeowners and renters by 25 percent.

For Northwest Public Radio, I’m Diane De Rooy.

Tuesday, July 18, 2006

News Release: Cosmetic Skin Resurfacing

Date: May 25, 1996

For Release: Immediately

Contact: Roseanne Hirsch, President & CEO, 206/806-2649

Luxar’s putting a new face on laser technology

Cosmetic Skin Resurfacing™ scanner gives laser surgery a facelift

Microsoft. Nintendo. Starbucks. Luxar.

Microsoft. Nintendo. Starbucks. Luxar.The first three names are familiar everywhere, known far and wide as successful, innovative companies who blazed trails for their unique products and technologies. All three started out small, and struggled. All three started in the Seattle area.

So did Luxar.

The small company from Bothell, Washington, is marking its third year of profitability in the field of medical lasers. The technology Luxar’s founder co-invented and patented nine years ago is now widely used in cosmetic laser surgery.

In the last few years, the popularity of laser skin resurfacing has grown to the point of being one of the most desired forms of aesthetic surgery.

But since long before the skin resurfacing trend, Luxar’s carbon dioxide laser systems were leading their class of in-office surgical tools. With the launch of its NovaPulse™ laser system in 1995, the practice of Cosmetic Skin Resurfacing™ (laser dermabrasion) became both accessible and affordable to doctors everywhere.

The NovaPulse laser comes with an assortment of accessories, including precision handpieces that work quickly and well in the treatment of damaged tissue of the perioral (mouth) and periorbital (eye) areas of the face.

Luxar today released the NovaScan™, a laser scanner designed for full-face CSR™.

The NovaScan received FDA clearance for laser dermabrasion on April 26, 1996, less than a year after its conception.

Luxar engineers developed the NovaScan as a NovaPulse add-on designed to meet the full-face CSR needs of aesthetic medicine. Satisfying doctors, as well as their patients, meant combining fast coverage with fine control of ablation depth (removal of skin cells) in one tool.

The NovaScan meets the challenge, performing full-face CSR in 24 minutes per patient.

The Luxar story

Luxar was incorporated late in 1987 by Dr. Katherine Laakmann, co-inventor of the sealed-off, RF-excited CO2 waveguide laser.

In the first year, Laakmann furnished Luxar’s ground floor with her A-team: engineers who could conceive, develop and deliver ingenious laser technology. Mike Levy signed on as director of research and development. Steve Wojcik, a mechanical engineer and designer, and Paul Diaz, an electronics engineer specializing in software development, were hired to develop the company’s own in-office laser system.

The team struggled to make ends meet while it developed products—and a cash flow. Team members shared housing to save costs, sometimes lending the company money or going without pay to buy time.

Using its incredible wealth of knowledge of CO2 laser components, the team built on Luxar’s foundation by designing and developing products for hospital laser companies.

Luxar’s first product was the Endoguide, a rigid endoscopic fiber and handpiece designed to work with surgical CO2 lasers with articulated arms. The Endoguide was launched in early 1989 for Surgilase.

Working with money they were earning, Laakman, Levy, Diaz and Wojcik spent the next year in development of Luxar’s own CO2 medical laser. To help make ends meet, Wojcik contracted with Laser Industries, the parent company of Sharplan, to develop a high-powered, 150-watt CO2 laser.

The sacrifices started to pay off when the LX-20 went into production in 1990. The 20-watt CO2 laser was a hit with doctors because of its flexible waveguide. Other laser systems used rigid, articulated arms and a series of mirrors to deliver laser energy to the tip. Luxar’s flexible fiber waveguide allowed a speed and control of hand and arm movements previously unknown to laser surgeons.

Luxar today

In 1995, Luxar launched its most popular product yet: the NovaPulse™, a CO2 laser that offers two different wave types of laser energy on demand, allowing doctors to opt for a laser instead of a scalpel in more and more surgical and cosmetic procedures.

Because of its record as the premier CO2 laser technology innovator, Luxar Corporation remains the leading supplier of CO2 lasers in the world.

Of the original A-team, three are still with Luxar. Wojcik is manager of research and development; Diaz is the executive director of engineering; and Levy is chief scientist for the company.

The company has thrived under the guidance of Roseanne Hirsch, the CEO who signed on a year ago. Company revenues are expected to reach $27 million in 1996.

And with the January 1996 hire of the company’s marketing director, Ken Craig, a more prominent corporate profile will be seen.

Current projects in R&D at Luxar include expanding the applications of the NovaPulse laser, and continued innovation in aesthetic medicine.

News Release: Introducing Roseanne Hirsch, CEO

Date: May 25, 1996

For Release: Immediately

Contact: Roseanne Hirsch, President and CEO, 206/806-2649

Aesthetic laser market looks good to Luxar’s CEO

Success of NovaPulse laser system points to company’s growth, maturity

THE PHOTO SHOOT WAS AN HOUR BEHIND SCHEDULE when Roseanne Hirsch, 48-year-old CEO of Luxar Corporation, poked her head out the door to check on the photographer.

“You know, this was supposed to happen an hour ago,” she said with a serious expression. “By now, I’ve passed my peak of attractiveness.”

Hirsch’s dry wit and deadpan delivery are the perfect complements to her tough and serious management style.

The release of Luxar’s NovaScan™ handpiece is the zenith of Hirsch’s no-nonsense management approach for the company she heads up. In her first year at the helm, Luxar’s sales have doubled, with $27 million in revenues projected before the next fiscal year begins.

“We’re the leading supplier of carbon dioxide lasers in the United States today,” she says, explaining the company’s phenomenal growth. “We have the strongest distribution system and are most conscientious about customer service.”

An important element of that service is Luxar’s R&D philosophy to resist planned obsolescence. When Luxar engineers streamlined their laser systems in 1995, their directive was to upgrade the last version of systems already in the field, allowing existing clients to have the latest in technology without paying to rebuild their systems from the ground up.

In the same spirit, the NovaScan handpiece, developed exclusively for Luxar’s trademarked Cosmetic Skin Resurfacing™ procedures, was designed to be used with the existing NovaPulse laser system, with a minimal upgrade required.

Hirsch points out that the ability to upgrade hardware that will perform aesthetic procedures is the doctor’s first step to dealing with the managed care dilemma.

“Cosmetic procedures are a cash business,” she says. “Doctors who are already using some combination of the NovaPulse™ system can venture into this market for a relatively small investment.”

Part of Luxar’s strategy that has really contributed to the company’s phenomenal growth is the versatility of the handpieces, culminating in the release of the NovaScan.

Hirsch developed her strategies and philosophies after a noteworthy career in the medical device industry, which included founding her own plastics injection molding business, as well as in stints at Medtronic, Inc., Phasecom and the I-Flow Corporation.

Under Hirsch’s guidance, the Luxar group will continue to develop products designed for aesthetic procedures, including hair removal and vein reduction. Simultaneously, engineers are looking at developing systems for medical imaging, as well as “cosmeceuticals,” products aimed at pre- and post-operative aesthetic surgery patients.

The glow of success surrounds everyone who’s a part of Luxar, owing in no small part to Hirsch’s management and vision. The fact that a recent FDA audit of the manufacturing facility resulted in a perfect review affirms that the she has the company on the right track.

The company’s immediate next goal is a major expansion into the European Community’s aesthetics market.

With Roseanne Hirsch at the helm, medicine can be assured of one thing: Luxar will continue to level the playing field by building powerful, high-quality, affordable surgical lasers for every doctor.

###

Date: May 25, 1996

For Release: Immediately

Contact: Roseanne Hirsch, President & CEO, 206/806-2649

Luxar’s putting a new face on laser technology

Cosmetic Skin Resurfacing™ scanner gives laser surgery a facelift

Microsoft. Nintendo. Starbucks. Luxar. So did Luxar. The small company from Bothell, Washington, is marking its third year of profitability in the field of medical lasers. The technology Luxar’s founder co-invented and patented nine years ago is now widely used in cosmetic laser surgery. In the last few years, the popularity of laser skin resurfacing has grown to the point of being one of the most desired forms of aesthetic surgery. But since long before the skin resurfacing trend, Luxar’s carbon dioxide laser systems were leading their class of in-office surgical tools. With the launch of its NovaPulse™ laser system in 1995, the practice of Cosmetic Skin Resurfacing™ (laser dermabrasion) became both accessible and affordable to doctors everywhere. The NovaPulse laser comes with an assortment of accessories, including precision handpieces that work quickly and well in the treatment of damaged tissue of the perioral (mouth) and periorbital (eye) areas of the face. Luxar today released the NovaScan™, a laser scanner designed for full-face CSR™. The NovaScan received FDA clearance for laser dermabrasion on April 26, 1996, less than a year after its conception. Luxar engineers developed the NovaScan as a NovaPulse add-on designed to meet the full-face CSR needs of aesthetic medicine. Satisfying doctors, as well as their patients, meant combining fast coverage with fine control of ablation depth (removal of skin cells) in one tool. The NovaScan meets the challenge, performing full-face CSR in 24 minutes per patient. Luxar was incorporated late in 1987 by Dr. Katherine Laakmann, co-inventor of the sealed-off, RF-excited CO2 waveguide laser. In the first year, Laakmann furnished Luxar’s ground floor with her A-team: engineers who could conceive, develop and deliver ingenious laser technology. Mike Levy signed on as director of research and development. Steve Wojcik, a mechanical engineer and designer, and Paul Diaz, an electronics engineer specializing in software development, were hired to develop the company’s own in-office laser system. The team struggled to make ends meet while it developed products—and a cash flow. Team members shared housing to save costs, sometimes lending the company money or going without pay to buy time. Using its incredible wealth of knowledge of CO2 laser components, the team built on Luxar’s foundation by designing and developing products for hospital laser companies. Luxar’s first product was the Endoguide, a rigid endoscopic fiber and handpiece designed to work with surgical CO2 lasers with articulated arms. The Endoguide was launched in early 1989 for Surgilase. Working with money they were earning, Laakman, Levy, Diaz and Wojcik spent the next year in development of Luxar’s own CO2 medical laser. To help make ends meet, Wojcik contracted with Laser Industries, the parent company of Sharplan, to develop a high-powered, 150-watt CO2 laser. The sacrifices started to pay off when the LX-20 went into production in 1990. The 20-watt CO2 laser was a hit with doctors because of its flexible waveguide. Other laser systems used rigid, articulated arms and a series of mirrors to deliver laser energy to the tip. Luxar’s flexible fiber waveguide allowed a speed and control of hand and arm movements previously unknown to laser surgeons. In 1995, Luxar launched its most popular product yet: the NovaPulse™, a CO2 laser that offers two different wave types of laser energy on demand, allowing doctors to opt for a laser instead of a scalpel in more and more surgical and cosmetic procedures. Because of its record as the premier CO2 laser technology innovator, Luxar Corporation remains the leading supplier of CO2 lasers in the world. Of the original A-team, three are still with Luxar. Wojcik is manager of research and development; Diaz is the executive director of engineering; and Levy is chief scientist for the company. The company has thrived under the guidance of Roseanne Hirsch, the CEO who signed on a year ago. Company revenues are expected to reach $27 million in 1996. And with the January 1996 hire of the company’s marketing director, Ken Craig, a more prominent corporate profile will be seen. Current projects in R&D at Luxar include expanding the applications of the NovaPulse laser, and continued innovation in aesthetic medicine. ###

The first three names are familiar everywhere, known far and wide as successful, innovative companies who blazed trails for their unique products and technologies. All three started out small, and struggled. All three started in the Seattle area. The Luxar story

Luxar today

Monday, July 17, 2006

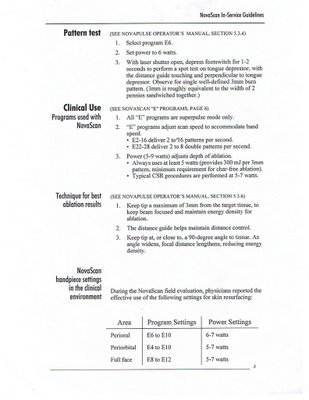

Abridged Laser In-service instructions

My first job was to reduce the number of words in the in-service introductory sections and replace them with images and more concise instructions. The Operator's Manual was still referenced, but that had also been abridged for the convenience of the end user.

The mission was to get the reader from unpacking to hands-on testing as quickly as possible so the laser could be put into service in the doctor's office at the earliest possible time.